Skip to main content

PCB Capabilities

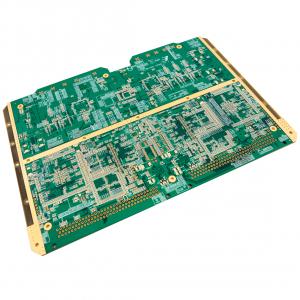

PCB Technologies

- Single Sided Conventional (NonPTH)

- Double Sided Conventional (NonPTH)

- Plated Through Hole (2 Layers)

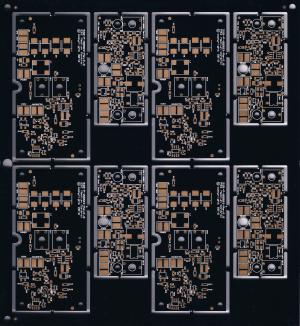

- Multi-Layers up to 20 Layers

- IMS (Metal Backed Substrates)

- Rogers, Taconic, Arlon & Nelco Laminates

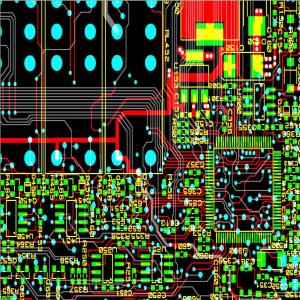

CAM Engineering

- 3 x Visual CAM and 1 x UCAM Software Seats

- Design Rule Checks and Design for Manufacture checks on all supplied data.

- Panelisation layouts to specific drawing requirements.

- In-house photo-plotting - Gerber Crescent 40 plotter.

- Photo-plotting resolutions up to 8,000dpi. (4,000dpi standard).

- Netlist creation for electrical test data.

- In-house Electrical Test data generation using UCAM software platform

Data Specifications

- RS274-X Gerber (preferred)

- RS274-D Gerber (aperture list required)

- DXF, DWG, HPGL and EPS file imports and conversions

- NC Data – Excellon Format 1 & 2 (preferred)

- Sieb and Meyer Format 1000 & 3000

Laminate Types

- FR4, FR2, Hi-Tg, Polyimide, BT Epoxy, CEM1, CEM3, IMS, Rogers, PTFE

- Material thickness available from 0.2mm up to 4.0mm.

- Finished copper weights up to 140µ (4oz)

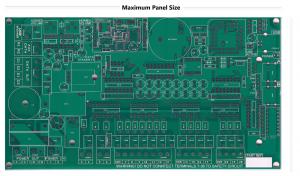

Maximum PCB Manufacturing Panel Sizes

- PTH & Multi-Layer – 508mm x 609mm (20” x 24”)

- Non PTH – 558mm x 762mm (22” x 30”)

- Rogers Materials 305mm x 457mm (12" x 18")

- IMS Substrates - 457mm x 609mm (18" x 24")

PCB Manufacturing Specifications and Tolerances

- Max. layer count – >10

- Min. track – 0.127mm

- Min. gap - 0.127mm

- Min. hole Ø – 0.25mm (Drilled)

- Min. slot Ø (peck drilled) – 0.6mm

- Min. annular ring – 0.15mm (above drilled hole size)

- Routed profile +/- 0.15mm

- Scored edge +/- 0.35mm

- Finished hole Ø tolerance (Plated) +/- 0.05mm

- 2nd stage drill Ø tolerance (Non Plated)+/- 0.05mm

- 2nd stage drill tolerance (positional) +/- 0.2mm

Electrical Test

- 2 x Double Sided Flying Probe

- All test data prepared & verified in-house.

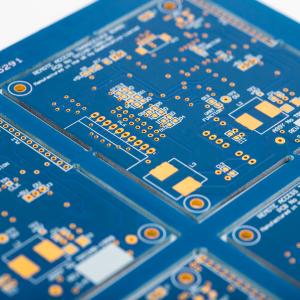

PCB Coatings

- Liquid Photo-Imageable Solder Resist (Wide choice of colours available)

- Liquid Photo-Imageable Component Ident (Wide choice of colours available)

- High reflectivity LED 900W White (suitable for LED lighting applications)

- High density yellow (suitable for ident marking on white solder resist)

- Peters SD2955 Peelable Solder Resist (Suitable for Lead Free Processing)

Surface Finishing

- Leaded Hot Air Solder Levelling – Non RoHS

- Lead Free Hot Air Solder Levelling – RoHS compliant (Sn100C Alloy)

- Immersion Nickel Gold – RoHS compliant

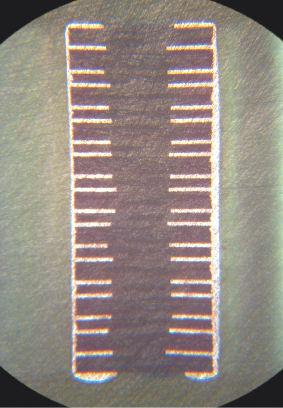

- Electrolytic Hard Gold – RoHS compliant

- Sterling ® Silver – RoHS compliant

PCB Quality Systems

- BS EN ISO9001-2015

- IPC-A-600 to latest Rev for Printed Circuit Boards

- IPC-A-610 to latest Rev for Electronic Assemblies

- In-house Certified IPC trainers for PCB and Electronic PCB Assemblies

- UL Approved (File no: E207295).

- In house laboratory facilities.